Reusing PVC Fittings

Why do I want to reuse PVC fittings?

Reusing PVC fittings can be cost effective if you’re a homeowner like me. If you’re a contractor type person then time is more important and not worth the effort. But as homeowners, we have time on our hands in a lot of our projects. This technique can save the homeowner quite a bit of money for a small amount of time and effort on large specialty type fittings.

PVC fittings or schedule 40 PVC fittings as they often are called are mainly used for moving water, this same material is used in electrical conduit type fittings. There is another PVC fitting labeled DWV fittings. These fittings with this designation are for drains, waste, and venting but because of their use, I would not recommend their reuse.

![By Tomwsulcer (Own work) [CC0], via Wikimedia Commons Mybusyretiredlife.com exposed DWV PVC_drain pipe](https://www.mybusyretiredlife.com/wp-content/uploads/2016/01/Mybusyretiredlife.com-exposed-DWV-PVC_drain-pipe-300x130.jpg)

DWV PVC_Drain Pipe

All PVC Fittings and Valves at – Amazon.com

The process of being able to reuse large or small PVC fittings is a simple one. The items and tools needed are the same:

- PVC glue medium grade

- A flame

- Slip joint pliers and or needle nose pliers

- Gloves

- PVC cleaner

- Old PVC fittings with pipe still in them

- A large space with good ventilation and no combustibles in the vicinity

- A short section of the same diameter pipe

- A large bucket of water

Something to know before you start the process

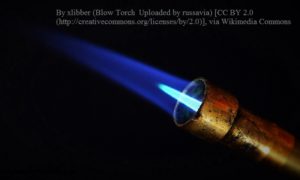

Blowtorch flame

Before you start the process you need to know what you want to achieve in order to remove the old pipe. PVC, when it gets hot(above 150°), is very soft. When PVC is hot it is very soft and it can change its shape. This is what we want for the old pipe but not for the old fitting. You don’t want the old fitting to get so warm that its shape(round) can change. When we get to the end condition the pipe inside the fitting is going to be soft and pliable, the fitting will be warm, but not soft enough to change shape. Should you “warp” your fitting see my post on fixing a warped fitting.

All Propane Torch Kits at – Amazon.com

So we “will not” be using a blow torch to heat the pipe as the blowtorch can take us past our end condition to quickly. We want the process to be slow and controlled. We are going to set the pipe on fire.

Heating The Old Pipe

Before we start warming up the pipe for removal lets set up the area for an open flame. Place a bucket of water nearby to cool the fitting after removal of the pipe. Remove any combustibles from the area where the open flame will be used. Secure a place for the fittings on a noncombustible surface.

Prepare the fittings by cutting off the pipe but leave 1/2″ of the pipe extending beyond the fittings. This extra pipe is needed to have material for the pliers to grab when we start to remove the pipe. Heating the old pipe requires the application of a light coat of glue to the inside of the pipe and only the pipe. Do not apply glue to the inside surface of the fitting. Work one side of the fitting at a time.

Wear gloves to protect your hands from heat when the pipe gets warm to hot. With the glue on the inside surface of the pipe use an open flame to ignite the glue and let it continue to burn while checking the condition of the pipe. Make sure the flame is out before you apply a second coat of glue if needed and a second burn to get the pipe hot enough to soften it.

Technique for removing the pipe

![By Touelia (Own work) [CC BY-SA 3.0 (//creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons Mybusyretiredlife.com Reusing PVC Fittings pipe in fitting](https://www.mybusyretiredlife.com/wp-content/uploads/2016/01/Mybusyretiredlife.com-pipe-in-fitting-300x251.jpg)

Pipe In Fitting

The technique is pretty simple to hold the fitting in one hand. With the other hand using the pliers grab the pipe extending from the fitting and start pulling and twisting the pipe toward the center of the fitting opening. Take care not to damage the fitting during the removal. Continue to work the pipe until it releases from the fitting or you have to reheat the pipe to further soften it. Repeat the procedure until the pipe is removed. Repeat the process on the other end of the fitting.

Cleaning up the fitting for reuse

Cleaning the fitting requires that it be cool to the touch and dry. Apply primer using the dauber from the can and continue to swab the inside surface of the fitting. You will notice that the old glue will start to dissolve after a while. When you think the old glue is completely dissolved inspect the fitting for any hard glue residue using your fingertips. If none is found inspect it for proper shape. You can use a short piece of pipe to check the fitting shape. If the shape is no longer round check out my article on Fixing Warped PVC fittings.

A successfully finished fitting will have all the openings primed, still be round and ready to be reused.

More information on the Material Safety Data Sheet click here

Article: The Difference Between Schedule 40 PVC And Schedule 80 PVC

Related Article: How To Cut Deburr Glue PVC Pipe

Related Article: Fixing Warped PVC Fittings

(By Tomwsulcer (Own work) [CC0], via Wikimedia Commons)

Thank you for sharing this informative article on the benefits of reusing PVC fittings. It’s helpful to know that there are several reasons why reusing fittings can be a good idea, including cost savings and environmental benefits.

I appreciate the explanation of the factors that can impact whether or not a fitting is suitable for reuse, such as the condition of the fitting and the type of PVC cement that was used. The tips for cleaning and preparing the fittings for reuse are also very useful.

Ben

Hello Ben,

Thank you for the comment. I am glad to hear that the post has gotten across the details of why a PVC fitting would be reused. I strive to give all the information necessary so that someone attempting this procedure or any procedure will be successful.

Good luck on any future endeavors,

RayC