Brother SE 400 tension problem

My wife came to me last night telling me about her sewing machine’s tension problem. I, of course, volunteered to look at it. I have never worked on any sewing machine. So I went to youtube.com. I learned a lot about tension problems for my wife’s sewing machine a Brother model # SE 400.

In the course of this learning, I found some excellent videos about tension problems. The first video Correcting Mistakes…. is 8 1/2 minutes long. The second video Bobbin Rescue! is 4 1/2 minutes long. The third video Fix For Sewing Machine… is 5 minutes long. The information contained in these three videos should work on any machine that uses bobbins, a bobbin case, and gets fuzz buildup. That is every sewing machine made. The persons doing the videos have well thought out processes. They cover as much informational territory as they can. These three videos cover the three problem areas, cleanliness, bobbins, and bobbin cases.

Getting the machine Fuzz Free

When I opened up my wife’s machine as per the video “Correcting Mistakes- Jammed Fabric Brother Sewing Machine”. I found a mess, fuzz buildup that makes the fuzz in the video look like a clean machine. When I asked my wife about it she replied: “I make the magic happen I don’t maintain my machine.”

So that’s how it got into this shape. It took about ten minutes with a brush to remove the large parts of the fuzz. I also found the fuzz packed into the feed dogs. So I had to pay extra attention to that area.

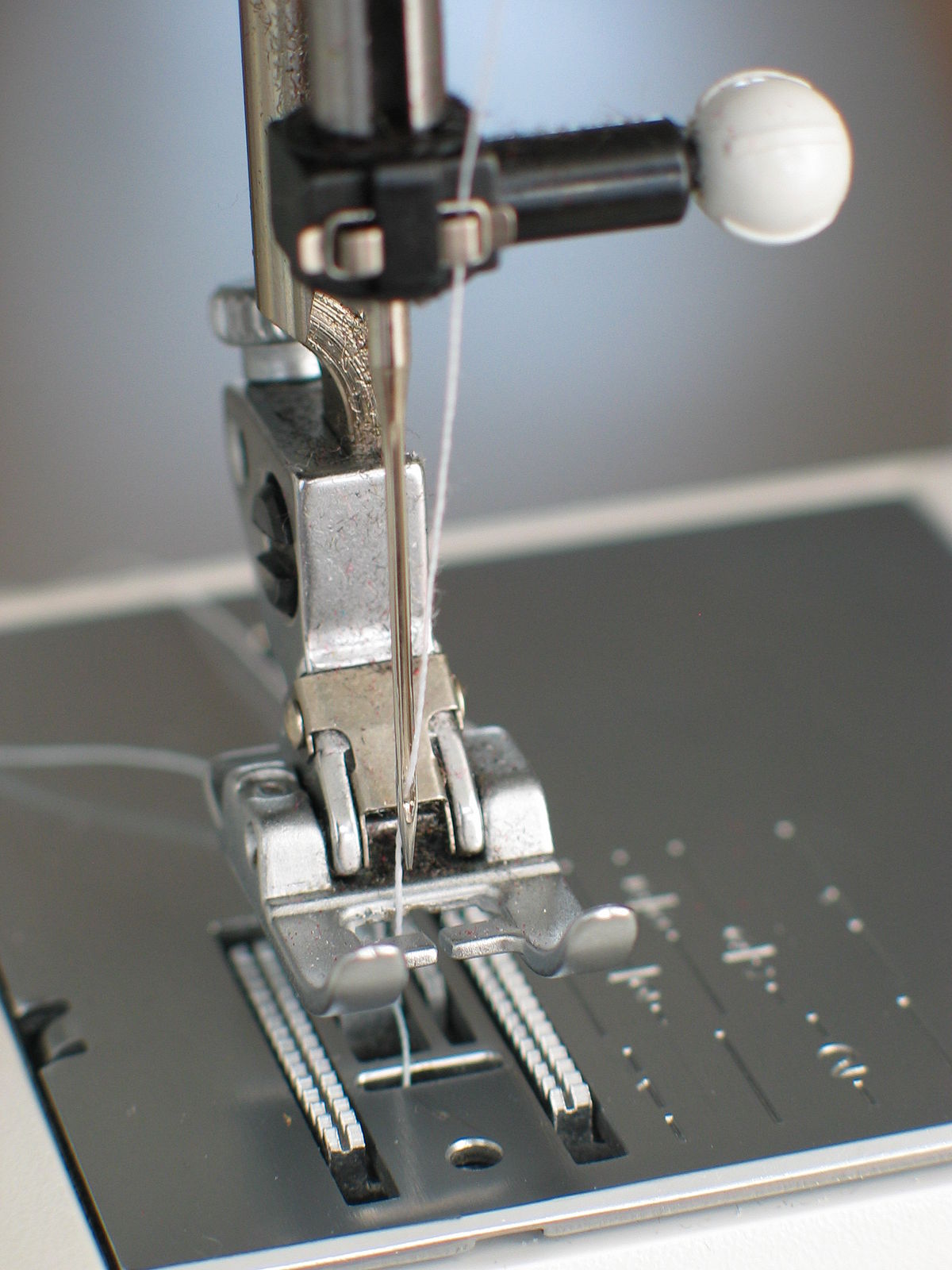

Feed dogs are the critical component of a “drop feed” sewing machine. A set of feed dogs typically resembles two or three short, thin metal bars, crosscut with diagonal teeth, which move back and forth in slots in a sewing machine’s needle plate. Their purpose is to pull (“feed”) the fabric through the machine, in discrete steps, in-between stitches.

From Wikipedia, the free encyclopedia

https://en.wikipedia.org/wiki/Feed_dogs

In the video, she uses a duster can to blow out the small fuzz. I have an air compressor with a blowgun nozzle that I used on my wife’s machine. A duster can is a good option if an air compressor is not in your future. For my wife’s machine, I needed industrial-strength air pressure to get it clean.

Related Post on air compressors

Bobbin Medic

In the second video “Bobbin Rescue!” she talks about bobbins. This is great information on the bobbins needing to be properly sized or having the right class for your machine. Then she goes on to tell you about how to mark them so that you will know that you have the right bobbin on the right machine. After that, she explains how bobbin winding will impact your machine. When I looked at my wife’s machine there was a rather large amount of thread wrapped around the bobbin winding shaft.

From a review

I found my wife’s machine had a birds nest of thread wrapped around the bobbin winding shaft. A small pair of needle nose pliers, a razor blade knife and about 10 minutes took care of that problem.

Let me clarify the use of a sharp knife, I only cut the thread, I didn’t want to accidentally score the winding shaft with the razor blade knife. If you should have this problem pull the thread away from the shaft with the needle-nose pliers. Cut the thread with the razor blade knife. Don’t cut the thread while it is wrapped around the shaft.

Also, the video shows how the thread moves around the bobbin case. This is an important piece of information for the next video.

The Bobbin Case Burrs

This last video gives you some great information not covered in the first two videos. This video is not about a Brother sewing machine but the information about the bobbin case is invaluable. He talks about the bobbin case being nicked by the needle and how he smoothed it out with some file and sandpaper work.

Remember how the thread moves around the bobbin case from the second video? After I removed the bobbin case from my wife’s machine. I checked the bobbin case’s surface. I found the problem he talks about in this last video. The needle nicked the plastic bobbin case. The needle created burrs where the thread makes contact with the case as it is pulled from the bobbin.

I used a point file to smooth it out. The point file is perfect for this application. The file is just a shade over five inches long and produces a very fine finish. Perfect for plastic. With light use, it came out so smooth that I didn’t need sandpaper.

From a review:

Conclusion

With the machine now capable of winding a bobbin correctly and the bobbin case is smooth and burr-free, and the machine fuzz-free I handed it back to my wife for testing. She came back with her finished product within an hour happy as can be. Mission accomplished. I think I’ll need to put her machine on a yearly cleaning cycle.

Related Articles: More Sewing Articles

(Deutsche Fotothek [CC BY-SA 3.0 de (http://creativecommons.org/licenses/by-sa/3.0/de/deed.en)], via Wikimedia Commons)

(Deutsche Fotothek [CC BY-SA 3.0 de (http://creativecommons.org/licenses/by-sa/3.0/de/deed.en)], via Wikimedia Commons)